EC500R Fortified Rice Production Line Recent Transaction Project >>

Sunpring-Fortified Rice Production Line Customer-from-Korea-in-2023-04

EC800R Fortified Rice Extruder

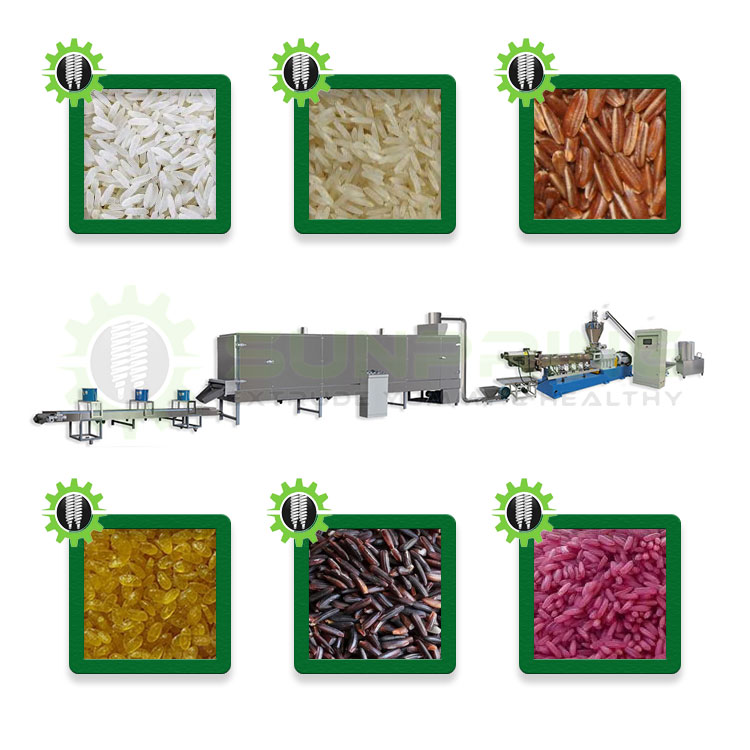

1. What is fortified rice extruder?

About Function:

To produce fortified grains using extrusion, the dough is made from a mixture of unfortified rice flour, vitamins and minerals, water and steam. The dough is then processed through an extruder to create a granular product similar to rice grains, which is then dried.

About Nutrition:

One kilogram of fortified rice contains iron (28-42.5 mg), folic acid (75-125 μg), vitamin B12 (0.75-1.25 μg). In addition to this, FSSAI has added zinc (10-15 mg), vitamin A (500-700 micrograms), vitamin B1 (1-1.5 mg), vitamin B2 (1.25-1.75 mg), vitamin B3 (12.3-20 mg) ) and vitamin B6.

About Capacity:

The capacity of the extruder is an important feature, our FRK twin screw extruders are available from 200 kg/h to 3000 kg/h. The EC800R Model is 800-900kg/h.

2. How about Sunpring‘s EC800R fortified rice extruder?

EC800R Fortified Rice Extruder

Flow Chart: Mixing → Conveying → Conditioner → Extrusion → Conveying → Drying → Cooling.

EC800R

EC800R

fotified rice production line can complete whole process from mixing to final products. Fortified rice making machine can extrude your recipe into nutrition rice. Key Features:

- End products: Fortified rice

- Capacity: 800-900kg/hr.

- Raw material: Broken rice flour, water, etc.

- Factory Requirement: a.Workshop: L-25M\ W-4M\ H 4M

b.Raw material warehouse: L-10M\ W-5M\ H-3M

c. Final production warehouse L-10M\ W-5M\ H-3M - Management and operator:

d.Manager one

e.Operator two

f. Dietitian one - Voltage/frequency:

380V/50Hz for three phase; 220V/50Hz for single phase. - Installation power capacity:

312.57kw.

Model |

Picture |

Feature |

Extrusion System |

|

Including barrel and screw, it is the main part of material heating, mixing, puffing and extrusion. There are two parallel screws in the barrel, which can be divided into co-meshing type, non-meshing type and non-meshing type according to the rotation direction and meshing mode of the screws. |

Transmission System |

|

Including the motor, gearbox and bearings, it is the part that drives the screw to rotate. The transmission system should provide sufficient torque and speed, and at the same time bear the axial force generated by the screw. |

Feeding System |

|

Including feeding device, metering device and control device, it is the part that supplies material to the barrel. Twin-screw extruder generally adopts forced metering feeding method, and different feeding devices can be selected according to different material characteristics and working conditions, such as single-screw type, twin-screw type, rotating disc type, etc. |

Heating and Cooling System |

|

Including heating device, cooling device and control device, it is the part to adjust the temperature of barrel and screw. Twin-screw extruders generally adopt electric heating and water cooling, and different temperature zones can be set according to different material properties and process requirements. |

Control System |

|

Including electrical control cabinets, instruments, sensors, etc., it is a component that controls the operating parameters and status of the twin-screw extruder. The control system should realize the monitoring, adjustment and protection of motor speed, material flow, temperature, pressure and other parameters to ensure the safe, stable and efficient operation of the twin-screw extruder. |

Mixing Process

A mixer stir water and all the material needed to make artificial rice.

Extrusion Process

Twin screw extrusion machine extrude the mixture out, the mixture form like regular rice at this step.

Drying Process

The dryer evaporates extra water on the surface of artificial rice.

Packing Process

The food packaging machine bagging sealed artificial rice in the bag, this is the last step before you delivering the products to your local retails shop.

Sunpring Factory 1

Sunpring Factory 2

Sunpring Factory 3

Sunpring Factory 4

- All

- Sunpring Fortified Rice Extruder News

- Sunpring Fortified Rice Production Line News

Want to know more about fortified rice production line business? Ask Now! We still have more types for your choose! Good price, best quality, local service!