EC500R Fortified Rice Production Line Recent Transaction Project >>

Sunpring-Fortified Rice Production Line Customer-from-Korea-in-2023-04

EC500R Fortified Rice Production Line

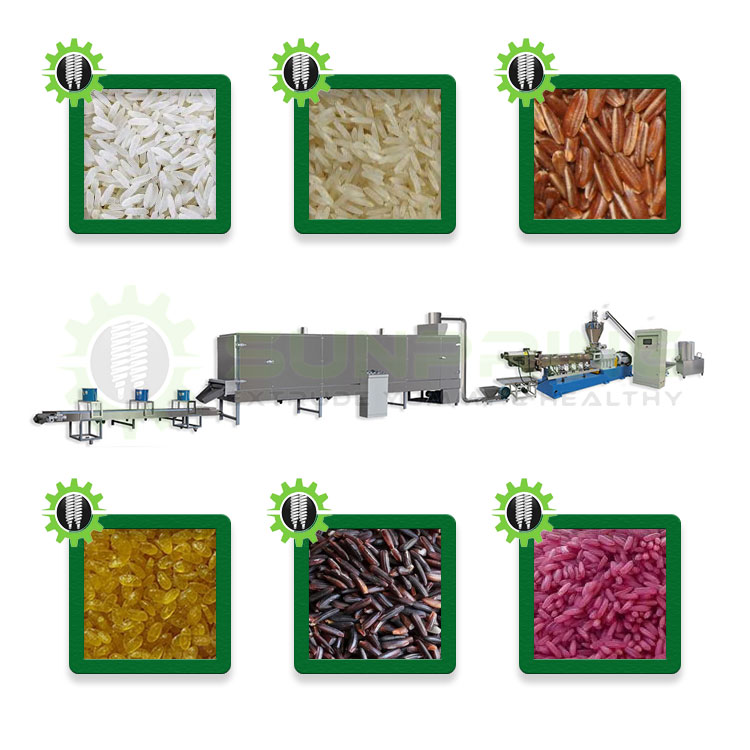

1. What is fortified rice production line?

About Material:

EC500R fortified rice production line uses rice flour, millet flour, broken rice, and buckwheat as basic raw materials.

About nutrition:

It also include various nutritional elements such as vitamins, minerals. In addition, dietary fiber can also be added to the raw materials. Squeezed, transformed to regenerate new fortified nutrients. Fortified nutritional rice meets people’s needs for balanced nutrition.

About capacity:

Output mainly includes: 500kg/h, 800kg/h, 1000kg/h, 1500kg/h, 2000kg/h, etc. Sunpring EC500R fortified rice production line capacity scope is 400-600kg/h.

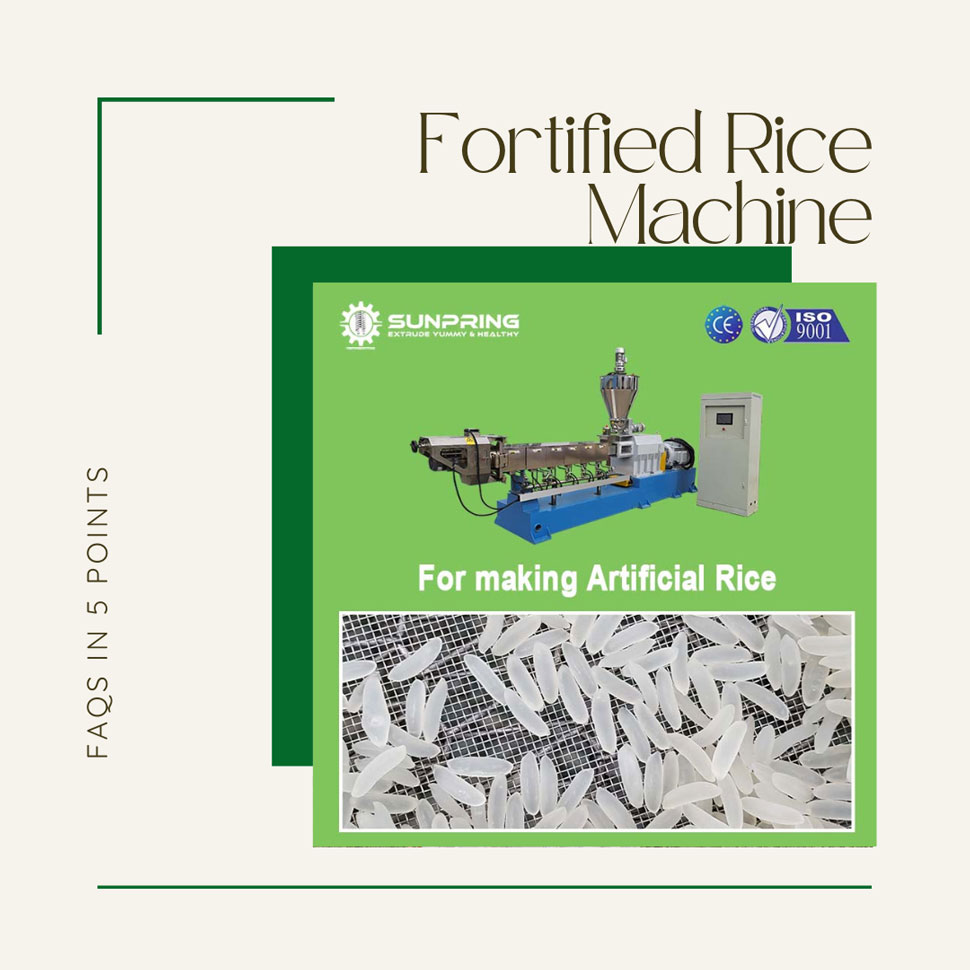

2. How about Sunpring‘s EC500R fortified rice production line?

EC500R Fortified Rice Production Line

Flow Chart: Mixing → Conveying → Conditioner → Extrusion → Conveying → Drying → Cooling.

Mixing Process

A mixer stir water and all the material needed to make artificial rice.

Extrusion Process

Twin screw extrusion machine extrude the mixture out, the mixture form like regular rice at this step.

Drying Process

The dryer evaporates extra water on the surface of artificial rice.

Packing Process

The food packaging machine bagging sealed artificial rice in the bag, this is the last step before you delivering the products to your local retails shop.

EC500R

EC500R

fotified rice production line can complete whole process from mixing to final products. Fortified rice making machine can extrude your recipe into nutrition rice. Key Features:

- End products: Fortified rice

- Capacity: 400-600kg/hr.

- Raw material: Broken rice flour, water, etc.

- Factory Requirement: a.Workshop: L-25M\ W-4M\ H 4M

b.Raw material warehouse: L-10M\ W-5M\ H-3M

c. Final production warehouse L-10M\ W-5M\ H-3M - Management and operator:

d.Manager one

e.Operator two

f. Dietitian one - Voltage/frequency:

380V/50Hz for three phase; 220V/50Hz for single phase. - Installation power capacity:

266.94kw.

Model |

Picture |

Total Power |

Capacity |

Feature |

Milling System |

|

34.12KW | 500-1000 kg/h | There is screw feeder for milling machine, controlled by VFD. |

Mixer |

|

4.0KW | 40kg/batch | Stainless steel and mild steel construction.

The raw material is mixed with water or other liquid additives. The discharge hole adopts the new handle-opened design, safe and sealed well. It takes six minutes for one batch. |

Screw Conveyor |

|

1.1 RV75 | 500-1000kg/h | Screw conveyor is used to convey mixed flour into feeder on extruder; there is wheel on screw conveyor, easy to move. Motor on bottom, easy to maintaince. Full Stainless steel structure; Four wheels for easy moving; Discharge door in the bottom for easy cleaning; |

Twin Screw Extruder |

|

111.7KW | 500-600kg/h | Extruder barrel consisting of segmented heads and rotating elements.

Total 7 Extruder barrel (Bimetallic barrel) with replaceable wear resistant liners. |

Vibratory Feeder |

|

0.55KW | 300-800kg/h | Vibratory feeder makes sure that rice go into air conveyor evenly. |

Negative Pressure Air conveyor |

|

2.2KW | 400-600kg/h | Function:

1.Stainless steel construction. 2.Air conveyor brings products into oven relying on the wind-force from the blower. 3.It is more suitable for the long distance conveying 4.Low energy-consumption, high efficiency. Motor for blower is 5.5KW 5.Transport pipe and cyclone made by stainless steel, it is hygiene and no leak out. |

Seven-layer Dryer |

|

112.5KW | 600-800kg/h | Speed controlled by inverter;

Function: To dry the product enough. 1.The electric heating pipes are installed in different layers。 2.The belt speed can be controlled by the control cabinet,to control the drying time of the product in the dryer,to make sure dry the product enough. |

Cooler Machine |

|

0.77KW | 500-1000kg/h | There is an exhaust fan which used to cooling rice. The air volume: 2664-5668m3/hr |

Sunpring Factory 1

Sunpring Factory 2

Sunpring Factory 3

Sunpring Factory 4

- All

- Sunpring Fortified Rice Extruder News

- Sunpring Fortified Rice Production Line News

Want to know more about fortified rice production line business? Ask Now! We still have more types for your choose! Good price, best quality, local service!