EC500R Fortified Rice Production Line Recent Transaction Project >>

Sunpring-Fortified Rice Production Line Customer-from-Korea-in-2023-04

EC1500R Fortified Rice Production Line

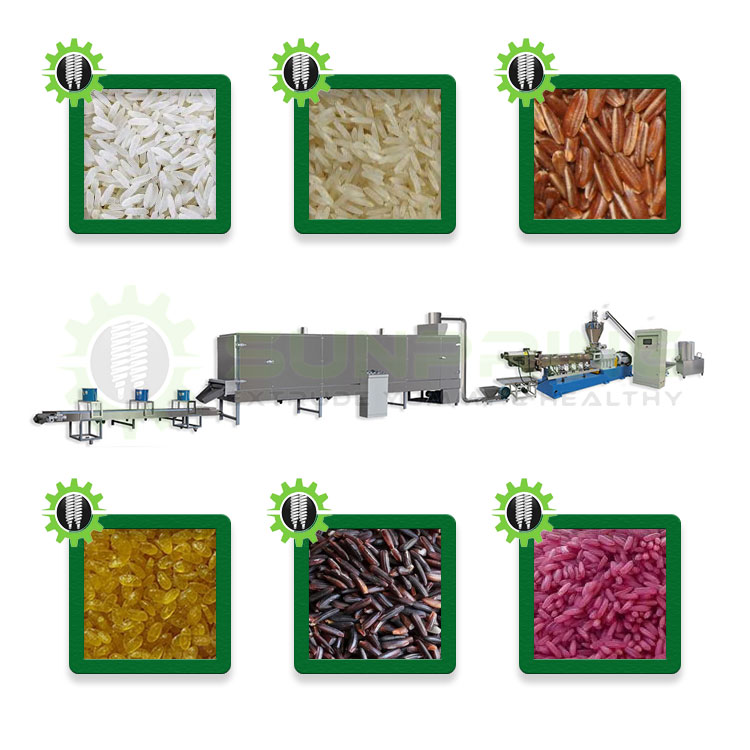

1. What is fortified rice production line?

About Material:

EC1500R fortified rice production line uses rice flour, millet flour, broken rice, and buckwheat as basic raw materials.

About nutrition:

It also include various nutritional elements such as vitamins, minerals. In addition, dietary fiber can also be added to the raw materials. Squeezed, transformed to regenerate new fortified nutrients. Fortified nutritional rice meets people’s needs for balanced nutrition.

About capacity:

Output mainly includes: 500kg/h, 800kg/h, 1000kg/h, 1500kg/h, 2000kg/h, etc. Sunpring EC1500R fortified rice production line capacity scope is 1200-1500kg/h.

2. How about Sunpring‘s EC1500R fortified rice production line?

EC1500R Fortified Rice Production Line

Flow Chart: Milling → Mixing → Conveying → Extrusion → Conveying → Drying → Conveying → Cooling.

Mixing Process

A mixer stir water and all the material needed to make fortified rice.

Extrusion Process

Twin screw extrusion machine extrude the mixture out, the mixture form like regular rice at this step.

Drying Process

The dryer evaporates extra water on the surface of artificial rice.

Packing Process

The food packaging machine bagging sealed artificial rice in the bag, this is the last step before you delivering the products to your local retails shop.

EC1500R

EC1500R

fotified rice production line can complete whole process from mixing to final products. Fortified rice making machine can extrude your recipe into nutrition rice. Key Features:

- End products: Fortified rice kernels

- Capacity: 1200-1500kg/hr.

- Raw material: Broken rice flour, water, etc.

- Factory Requirement: a.Workshop: L-25M\ W-4M\ H 4M

b.Raw material warehouse: L-10M\ W-5M\ H-3M

c. Final production warehouse L-10M\ W-5M\ H-3M - Management and operator:

d.Manager one

e.Operator two

f. Dietitian one - Voltage/frequency:

380V/50Hz for three phase; 220V/50Hz for single phase. And can be design according to customer’s Local voltage. - Installation power capacity:

340.44kw.

Model |

Picture |

Total Power |

Capacity |

Feature |

Stainless Steel Milling System

|

|

52.75KW | 1300-1500 kg/h | Two 60-mesh screens, two 80-mesh screens, two 100-mesh screens, five screen frames (40/60/80/100/120 mesh) Function: To grind grain into powder。 It features a simple structure, firm and stable operation and good crushing effect, the crushed material can be discharged directly from the grinding chamber of the host machine and the desired granule size can be obtained by installing screens with different apertures. The inner surface of the enclosure becomes smooth through processing, thus changing the powder residual phenomenon due to the coarse inner surface of the previous models. As a result, the production can better conform to the state standard and the GMP requirement. Material: the contact part is stainless steel Combined with pipeline, material receiving, dust removal, induced air and electrical control systems, there is an induced draft fan for negative pressure suction collection in the crushing process. The whole crushing process is carried out in a closed environment, thus avoiding dust pollution and achieving a dust-free effect. |

Ribbon Blender |

|

4.5KW | 200kg/batch | The ribbon blender used to mix raw material and water, there are two ribbon blenders which using interchangeably; there is a pump and spraying nuzzle system which used to pump water into ribbon blender for mixing. |

Screw Conveyor |

|

1.5 RV75 | 500-1000kg/h | Screw conveyor is used to convey mixed flour into feeder on extruder; there is wheel on screw conveyor, easy to move. Motor on bottom, easy to maintaince. Full Stainless steel structure; Four wheels for easy moving; Discharge door in the bottom for easy cleaning; |

Three Screw Extruder |

|

193.0KW | 1200-1500kg/h | Screw made by Cr12MoV; Super torque gear box with water cooling on lubrication oil system; three screw feeder; Extruder rotating elements also constructed of special hardened alloy stainless steel. Water injection device is included Motor with frequency control,can adjust according to material and product,so to meet different production demand. With forced oil lubrication system,promise long service life. |

Water Chiller |

|

2.9KW | Volume of water tank: 60Kg | Water chiller Function:

This machine used together with the extruder and to cool the extruder and get temperature control precisely. |

Water Injection Machine |

|

2.75KW | Dimension(m): 1.2×1.0×1.8 | Pump: flow control pump pump controlled by VFD;

Pipe connection: Clamp, easy to assemble Cylinder: jacket tank; water lever indication device; Weight: 100Kg The water injection machine’s function is to add water to the barrel extruder. The amount of water in the water injector matches the amount of material in the feeder according to formula. So it is no need put water on mixer manually during you do raw material mixing. |

Air conveyor |

|

2.2KW | Diameter of pipe: 159mm | Function:

It is more suitable for the long distance conveying Low energy-consumption, high efficiency. Motor for blower is 2.2KW Transport pipe and cyclone made by stainless steel, it is hygiene and no leak out. Air conveyor brings products into oven relying on the wind-force from the blower. Food contact part is stainless Steel |

Vibratory Feeder |

|

6.22KW | 1200-1500kg/h | Vibratory feeder makes sure that rice go into cooler machine evenly. 1.Remove the product not in demanded size by vibration. 2.Make sure the fortified rice will not stick together. 3..Food contact part is stainless Steel. |

Powerful Cooler Machine |

|

6.55KW | Dimension(m): 5.0×0.6×1.2 | Function:

To cool down the product ready for packing. Cooling conveyor used to convey the product meanwhile cool it down so the product would be ready for packing. It will cause the surface to be dry and will not stick Fan evenly blow cold air on the product surface, good cooling effect Cooling and conveying at the same time, save production time. The air volume: 2664-5668M3/hr; There are two exhaust fan which used to cooling rice, each one is 3kw. |

Negative Pressure Air Conveyor |

|

5.5KW | Dimension(m): 2.0×1.3×2.8 | Function:

It is more suitable for the long distance conveying Low energy-consumption, high efficiency. Motor for blower is 5.5KW Transport pipe and cyclone made by stainless steel, it is hygiene and no leak out. Air conveyor brings products into oven relying on the wind-force from the blower. pipeline is stainless Steel or PVC |

Steam Dryer |

|

37.35KW | Dimension: 12000*2800*3600mm | Input There is swing spreader at entrance; arm moving angle can be adjustable; no residence time at the end of movement; there is input air lock which control material and air; swing spreader is controlled by VFD;

S.S.plate Belt.the belt adopt stainless steel plate;there is hole bar on plate, 1.2mm width; back plate on belt is available; there are two spreader device on each layer which used to make feed evenly on plate; there is big door which locked by container lock in front side, back side, right and left side, for cleaning and maintance; there is self cleaning system on the bottom layer, small mince and waster will collected automatic, waste will be brought by a screw conveyor. Driving system.It is three-layer structure; two reducer motor control belt; motor controlled by VFD; Insulation plate.Four side of dryer with insulation plate to avoid heating loose; plate thickness is 64mm; door is locked by container lock with food grade rubber seal which can be against high temperature; Hot wind channel.there is crossflow technology of hot air circulation system; hot air go through the belt and get out from bottom and middle; then it enter into heating exchanger or moisture moving system; the distance between belt to belt is very important. Fresh air.fresh air go into dryer through entrance on the top of the dryer; there is air filter for fresh air in; adjustable plate is available for fresh air in; there is maintance door for heating exchanger on the top of dryer; there is air filter for heating exchanger; Moisture moving.there is moisture moving pipe system and motor; air out controlled by adjustable plate; moisture moving motor controlled by VFD Steam exchanger.It is made by carbon steel and designed for pressure 1.5MPa; Circulation system Hot air is drived by a 1440rpm motor with impeller; the shaft which connect impeller and motor is special design because of high working speed and face hot air environment, to ensure long life time with high speed and not lack of lubrication oil. |

Three Layer Cooling Machine |

|

6.05KW | Dimension(m): 5.0×1.3×1.6m | It has stronger and faster cooling performance than general cooling equipment. |

Sunpring Factory 1

Sunpring Factory 2

Sunpring Factory 3

Sunpring Factory 4

- All

- Sunpring Fortified Rice Extruder News

- Sunpring Fortified Rice Production Line News

Want to know more about fortified rice production line business? Ask Now! We still have more types for your choose! Good price, best quality, local service!