FAQs for Sunpring FRK Rice Machine

Jinan Sunpring Extruder tell you the FAQs for FRK Rice Machine in 5 points.

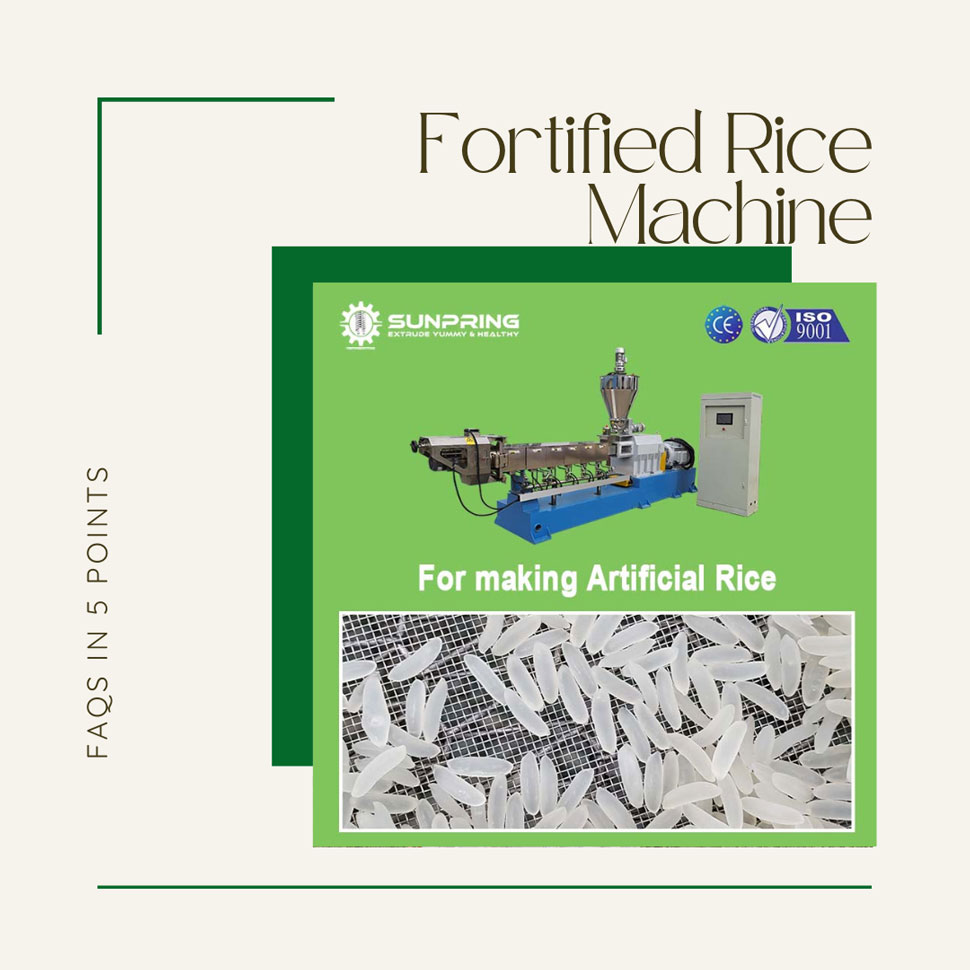

Problem 1: What is fortified rice making machine?

Answer 1:

Fortified Nutritional Rice Making Machine

A twin screw extruder is a machine consisting of two intermeshing, co-rotating screws mounted on splined shafts in a closed barrel. The screws are tight and self-wiping, which eliminates stagnant zones over the entire length of the process section.

Problem 2: How do you manufacture fortified rice?

Answer 2:

First, coating or extrusion technology is used to produce fortified kernels. Second, the fortified kernels are blended with non-fortified rice at a ratio of 0.5% to 2% to result in fortified rice. Coated fortified kernels are produced by coating rice grains, typ- ically head rice, with a liquid fortificant mix.

Problem 3: What is the cost of fortified rice manufacturing unit?

Answer 3:

Automatic Fortified Rice Making Machine, Three Phase, SS 304 at Rs 4200000/piece in Noida.

Problem 4: How do you know if rice is fortified?

Answer 4:

How can a beneficiary distinguish between fortified rice and regular rice? Fortified rice will be packed in jute bags with the logo (‘+F’) and the line “Fortified with Iron, Folic Acid, and Vitamin B12”.

Problem 5: What is difference between rice and fortified rice?

Answer 5:

Fortified rice kernels (FRK) are produced from this mixture using an extruder machine. The kernels resemble rice grains. FRK is added to non-fortified rice in ratio ranging from 1:50 to 1: 200 ( ideal is 1:100) resulting in fortified rice nearly identical to traditional rice in aroma, taste, and texture.

You May Like:

1) Fortified rice extruder

2) Fortified Rice Production Line

Write to you in front of the screen:

If you want to get more business tips about our machine, please feel free to contact us, we will provide you with comprehensive solutions from raw materials to production.

Learn More About FRK Rice Machine Today